Resistivity-

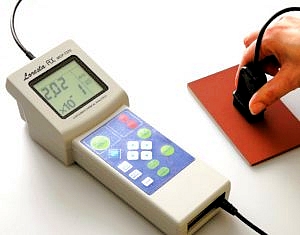

The mobile hand-

It is suitable for simple process or quality control.

To determine the specific resistances, a fixed correction factor (RCF) is used. The fixed RCF allows a sufficiently accurate calculation for quality control.

The measuring device works according to the 4-

The Loresta series offers a choice of 4-

To simplify the measurement method and calculate the correction factors, all four electrodes are at an equidistant distance from each other. The electrodes are usually arranged collinearly, but other arrangements, such as the square, are possible.

The two outer electrodes carry an impressed direct current, when the two inner electrodes pick up the voltage on the surface of the sample. Thus, the electrical resistance can be determined.

Up to 1000 measurement results are automatically stored and can be transfered via USB stick.

The Resistivity Measuring Systems of Nittoseiko Analytech have been designed to ensure easy RCF calculation and thus resistivity is measured in a simple test procedure.

With the devices Hiresta-

For over 40 years, the measuring instruments have been convincing due to their first-

Hiresta -

Loresta -

Loresta -

Loresta -

The Loresta GX is used to measure conductors and semiconductors in the lower resistance range.

Measuring range: 10-

It is used to measure the surface resistivity (Ω / cm)or the volume resistivity (Ω · cm)

electrical conductivity (S / cm) in the low-

The Loresta-

The method is based on the four-

The electrodes are usually arranged collinear, so the two outer electrodes carry an impressed direct current while the two inner electrodes pick up the voltage on the surface of the sample and the electrical resistance can be determined precisely.

The resistivities are obtained by applying the correction factor and including the thickness of the sample.

The Loresta GX has a mode that allows measurements of silicon wafers.

A color 7.5 "TFT LCD touch display facilitates reading and menu navigation. In addition, the data can be transferred via USB interface. The automatic auto-

The applied voltage can be choosen selectively, so that also measurements of materials with a very low conductivity are possible.

Loresta -

The Resistivity Correction Factor (RCF) is changed with the sample shapes and sizes as well as measuring positions, using the 4-

If the sample size is small or the measuring position is near the sample edge, the peak of the electric field becomes higher to yield a high resistance. This is caused by the electric energy being contained in the sample.

The correction factors RCF (S) and RCF (V) of the ring electrode probe are determined by the electrode diameters. Correction factors of probes is registered previously in Hiresta-

The Resistivity Correction Factor is used to obtain correct values for the volume or surface resistivity by forecasting such difference in the peak of the electric energy. The electric potential Φ(r) in an optional point in a sample and is calculated by solving a Poisson’s equation under a specific condition.

Poisson‘s Equation: ∇2 Φ(r) = 2 ρv I [ δ (r-

The Loresta-

The 4-

Resistivity measurment , what’s about ?

The Hiresta -

Measuring range of 103 -

It works with measuring heads, which are equipped with concentric ring electrodes and uses correction factors to determine the specific resistances. However, these are exclusively dependent on the geometry of the measuring head electrodes, so that a correction of the measuring position is not required. The Hiresta-

In conjunction with the optional insulating UFL Table (RMJ 354), the specific resistance [Ω ∙ cm] can also be measured exactly.

29 steps of applied voltage with Auto Sweep Function enables measuring voltage dependence of resistance value .Up to 2000 measurement results can be exported to USB memory stick

The conductivity meter impresses with its compact design, a color 7.5 "TFT touch display and user-

Hiresta -

The multimeter, equipped with 2 terminals, is a cheap and simple instrument for measuring voltage, current and resistance. However, the conventional 2-

In the case of the 4-

Then, multiplying the measured resistance (R in the unit of Q) with the sample thickness (t) and the Resistivity Correction Factor (RCF) derives the volume resistivity. In this way, the 4-

The Powder Measuring System MCP-

Key features:

- Easy sample change and cleaning

- 4-

pin probe for precise measurement of low range resistivity - Ring probe for high range resistivity

- Powder is pressed in a cylindrical shape for measuring

Application:

Powder materials of carbon products:

Materials used for rechargeable battery electrodes, Li-

Metal powder:

Materials used for battery electrodes, thin film materials

such as copper powder or ITO powder, for circuit board

materials, conductive paste and electro conductive paint.

Others:

Printer toner, magnetic material such as ferrite, food, nano fibers, surface coating… and thousand other application.

Powder Measuring System MCP-

Powder Measuring System MCP-